Have you ever tried to build a campfire using logs from a freshly cut down tree? It doesn’t work very well does it? But if you build a campfire from logs from a tree that had been cut down a couple years before, it burns easily. You may also notice that the log from the freshly cut tree is a lot heavier then the log that was cut a couple years ago. That’s because a tree draws moisture from the ground in order to live. When you cut it down, that moisture is still trapped within the wood, but over time it evaporates out. So a log from a freshly cut tree will weigh more than one that’s been down for a while because of the weight of the water.

So why’s this important? Well, we know that the wood is going to dry over time. As it drys, its shape changes and it can even start to twist, bow, and even crack. We don’t want to start working with it only to have it twist or crack on us, so we wait until the wood is dry before working with it. This may take a couple years to dry to the point that we can start working with it, so lumber yards will use Wood Kilns to dry the wood faster. Figure 1 shows an industrial wood kiln. A wood kiln circulates hot air around the boards in order to dry them quicker. Notice that the boards are stacked on top of each other with a space between them. That way all the board’s surfaces are exposed to the circulating hot air allowing the board to dry quicker as well as dry evenly.

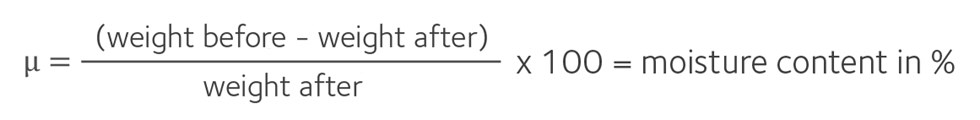

The lumber yard doesn’t completely dry the board. There’s still some moisture left in the wood. We call this the wood’s moisture content. This is a percentage of the amount of moisture left in the board. This is calculated as the weight before drying minus the weight after drying divided by the weight after drying, then multiplying that times 100 in order to get a percent as follows :

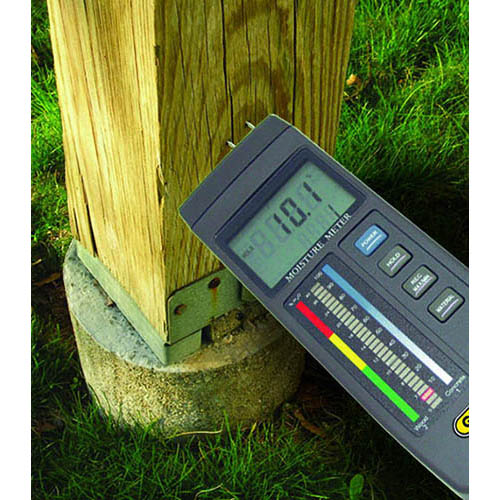

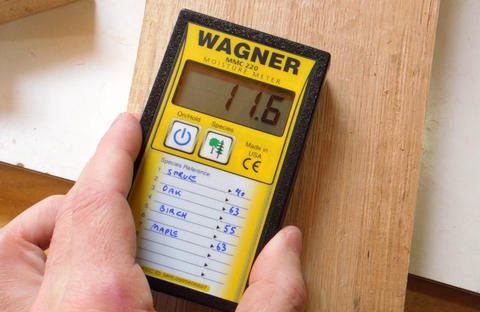

Didn’t know we were going to have to do math did you? Well you really don’t. We use moisture meters to determine the wood’s moisture content. Figure 2 shows a Pin Style Moisture Meter. It has two pins that you press against the grain of the board. Figure 3 shows a Contactless Moisture Meter. All you have to do with this style is lay it on the board.

Normally wood that you purchase from a lumber yard will have a moisture content between 7%-19%. Woods for interior projects you’ll want between 6%-8% moisture content and exterior projects are usually 9%-15% moisture content. Why’s this important? The lumber will absorb or evaporate moisture depending on the humidity of the environment that it’s in. Indoors the humidity is relatively low and pretty consistent. Outdoors the humidity can vary and in many cases it can be high. Depending on the humidity the wood will reach moisture content equilibrium, or a point at which it will no longer gain or loose moisture. Woodworkers use the term acclimate. You want to acclimate your wood for the environment that it’s going to be in before starting to work with it. Meaning that you’ll let it adjust to that environment (humidity level). Otherwise the wood could twist or crack once you move it into its intended environment. If you’re working on a project that’s going to remain indoors, you’ll want to work on it in a shop with a controlled environment. Meaning that the shops temperature and humidity is roughly the same as that of a normal house.

In some cases, like with music instruments, we’ll want an even lower moisture content (5%-6%), so they’ll have a small kiln in the shop. Once the wood is at the level of moisture they want, they’ll start woodworking it. Many times they’ll seal it afterwards in order to maintain the wood at that level of moisture content.

So, prior to starting your next woodworking project, you’ll want to know what environment you plan on using it in (indoors vs outdoors). Then establish the required moisture content you’ll need your wood at. This will save you the headache of having your project twist and crack on you.